Laserinterferometric vibrometers – precise, non-contact, flexible

Laserinterferometric vibrometers based on a Michelson interferometer

Mechanically coupled sensors have traditionally been used to measure vibrations. However, the general, continuing trend towards miniaturization is placing entirely new demands on measuring systems that measure the motion of objects through a wide frequency range and a down to sub-nanometer resolution. This is where laserinterferometric vibrometers from SIOS Messtechnik GmbH come in. These laserinterferometric vibrometers enable contactless, non-retroactive measurement of macroscopic and microscopic objects movement at frequencies from 0 to 5 MHz and resolutions in the subnanometer range. Systems like this are ideally suitable for applications in which the vibrations of hard-to-reach objects need to be analyzed.

The design of a laserinterferometric vibrometer is based on that of a Michelson interferometer, in which a coherent beam of light is split into two partial optical beams: a reference beam and a measuring beam. The reference beam has a fixed length. The measuring beam is focused on the surface to be measured and its length changes with the distance to the measured surface. After the measuring beam has been reflected from the surface the two returning partial beams interfere with one another. Their phase difference is proportional to the displacement of the measured surface. The phase difference is therefore the value being measured. This measurement can also be translated to international unit standards because the laser frequency follows a linear scale.

Optimized vibrometers for optically rough surfaces

Laserinterferometric vibrometers are interferometers that have been optimized for measuring optically rough surfaces. Their most important feature, which distinguishes them from other length measuring interferometers, is that they have a lense which focuses the measuring beam on the measuring point. Reflection from an optically rough surface creates a speckle pattern. The sensor head is designed to ensure a good signal-to-noise ratio, even when such a speckle pattern occurs. However, focusing the measuring beam limits the measuring range to a few mm depending on the reflectivity of the surface. This is not usually a problem in vibration measurement because the amplitude of the measured vibrations normally is quite small. Normal displacement measurements can also be made within the available measuring range.

Helium-neon lasers ((He-Ne laser) are used as the light source for length and vibration measurements because their properties of coherence and frequency stability are crucial for metrology. The measuring head in series LSV-NG vibrometers is coupled via a fiber-optic cable in order to keep the head relatively compact and free from thermal radiation. The reference mirror in the sensor head can be modulated in order to simplify calibration and improve performance. The vibrometers are available in two versions: with fixed focal length lense and with zoom lense to focus the measuring beam. The second version enables the distance between the measuring head and the measuring point to be freely adjusted between 24 cm and 2.5 meters. This allows a great deal of flexibility in the measuring set-up and the measuring instrument can be used for a wide range of different applications.

Design of the electronic processing unit

The He-Ne laser and the electronics for processing the interferometer signals received from the measuring head are housed in a 19 inch processing unit. The signals are processed by multiple microprocessors and quickly programmable logic gates. The reference mirror and the variable input amplifier are also controlled by these microprocessors and logic gates. The processing unit has a modular structure, which enables the measuring systen to be adapted flexibly to an application by installing various signal processing cards. It is possible to accommodate the processing of up to two sensor heads in one 19-inch device.

The data capture can be synchronized with external events. This is achieved by using a trigger input with an extremely short response time. This also allows of the phase of an object to be measured at a known level of excitation.

The evaluation unit can be equipped with different interface cards depending on its intended use:

The PC-interface card provides a USB and an RS232 interface that enables connection to a PC. It also provides a trigger input for synchronizing the vibration measurement with an external source of excitation. This processing card can be used to control various functions of the vibrometer and to recieve signals with a maximum sampling frequency of 12.5 MHz (corresponding to a maximum possible signal frequency of 5 MHz) and a maximum data block length of 65535 values. The application programming interface (API) for this card is available for the user. A DLL, a Matlab library and corresponding VI modules support integration into your applications.

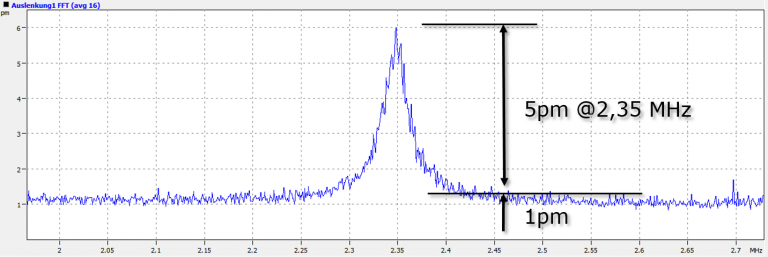

The parallel interface card outputs the demodulated interferometer signal as a digital, parallel 36-bit word. The resolution (an LSB of this word) corresponds to approximately 5 pm. The parallel 36-bit value is output with very low latency at a scanning rate of up to 12.5 MHz. This facilitates use of the full possible bandwidth of 5 MHz. In this case, the data block length depends only on the PC procesing and is not limited by the hardware. Typical fields of application for this interface are high-resolution frequency analyses of forced vibrations of micro-objects. As an example, a paralell input card from National Instruments can be used to integrate this interface on the PC side.

Vibration analysis systems often provide analog inputs for the sensors. The analog interface therefore has an analog output for integration into systems of this type. This enables conventional vibration sensors to be easily replaced by laserinterferometric vibrometers. The dynamic range of the series LSV-NG vibrometer is far greater than the measuring range of conventional sensors, as is the analog resolution achievable with reasonable effort. The measuring range mapped at the analog output can therefore be adjusted in seven stages (± 0.63 µm to ± 2.6 mm) to adapt to different fields of application. This is normally done with a rotary knob on the front panel, but the range can also be switched by software via the PC interface. An additional input for resetting/zeroing the analog signal further simplifies use. In total the analog interface card offers 16-bit resolution with a maximum output rate of 10 MHz.

Although the various interfaces available with the series LSV-NG laserinterferometric vibrometer can be integrated into almost any measuring system, our experience has shown that the majority applications involve stand-alone operation with PC software. The InfasVIBRO software controls the vibrometer via the USB or RS232 interface or via a DIO card from National Instruments (PCIe-6535) in combination with the vibrometers high-speed parallel interface. The software enables vibration signals to be displayed, saved and preprocessed. Recording of the raw signals enables the measurements to be analyzed offline without restrictions. A configurable export in the ASCII format enables both raw and preprocessed signals to be further processed. For integration into independent applications, InfasVIBRO can be controlled by a simple protocol via TCP-IP. Automation of longer measuring sequences can be done with the built-in simple scripting language. Here it is also possible to control som XY-tables and most frequency generators by using the correct interface.

Applications

LSV-NG series laserinterferometric vibrometers can be used in all fields of application where mechanical vibrations have to be analyzed and measured without contact. Its main advantages in comparison to other vibration measurement methods are its contactless and thus non-retroactive mode of operation, the large measuring range with a distance resolution of few picometers in the time domain and, of course, the frequency range from 0 Hz to a maximum 5 MHz. The vibration spectra, natural frequencies and modes of vibration can also be determined. Multicoordinate measurements and differential measurements can be made by using multiple systems.

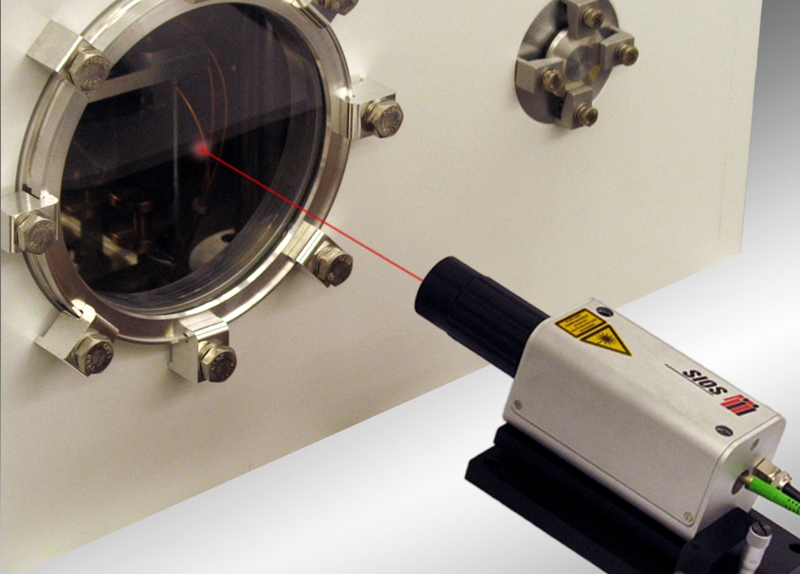

A special version of the series LSV-NG vibrometer which can work in vacuum is possible, but is very technically complex. However, it is often possible to complete such measurements by placint the measuring head outside the window of a vacuum chamber and aiming the laser beam through said window. By focusing the beam, measurements on or through glass surfaces are possible. This makes it quite easy to measure objects in a vacuum.

Conclusion

The laserinterferometric vibrometer is a valuable tool for all applications in which precise, non-contact measurement of object motion is required. The contactless mode of operation provides a means of quickly analyzing objects in many different positions without any mechanical influence by the sensor. The system stands out with its high precision and resolution and its very wide frequency range. The adaptable measuring range, made possible by the zoom lense, the wide range of interfaces for the evaluation electronics as well as the comprehensive software support make the series LSV-NG vibrometer an important measuring instrument in production, quality assurance, and research and development.

Situable products and solutions

Vibrometer with variable focal length

variable working distance from 240 mm to 2500 mm

Vibrometer with fixed focal length

high-resolution vibration measurement with fixed working distance and frequencies up to 5 mHz

Vibrometer with exchangeable lens attachment

high-resolution vibration measurement with exchangeable lens attachment