Interferometers with plane mirror reflector from SIOS Meßtechnik GmbH stand out with their high accuracy, large dynamic range and simple handling. Measurements with these systems are traceable and, with a linearity below ±1.5 nm, they are strictly linear. These interferometers only need a single measuring beam per measuring axis, which is reflected back into itself by a reflective surface. For short measurement lengths of up to 2 meters a mirror is used as a reflector. Due to a special optical arrangement in the interferometer these systems work at a measuring mirror tilt of up to ± 1.5 arcmin. The relatively small tilt invariance minimizes the often neglected second order measurement errors. The measuring mirror can also be shifted laterally, as is the case with x-y planar tables. For longer measurement lengths or stronger tilts (up to ± 12.5 °), these interferometers can be equipped with a compact, tilt-invariant reflector.

Other advantages of interferometers with a single measuring beam per measuring axis include the simple construction of Abbe error-free measuring arrangements and problem-free beam modifications. For example, the measuring beam can be guided through a lense or focusing optics. In addition, the flexible design of multi-beam interferometers is used for simultaneous detection of multiple movements or degrees of freedom. The triple-beam laser interferometers (Fig. 1) represent an evolution of the single-axis interferometers with plane mirror reflectors.

Triple-beam laser interferometers are measuring systems whose beams are supplied by only one laser but evaluate three separate interferometer channels. Particular attention was given to a completely symmetrical optical design so that three length values can be recorded simultaneously down to the nanometer. The tilt angle of the measuring mirror can be determined with high precision from the difference between two length values and the corresponding beam spacing. The synchronous data transfer of all measuring channels is given.

Thanks to their compact design, triple-beam interferometers for high-precision length and angle measurement can be easily adapted to a wide variety of measuring tasks and integrated into existing setups. The standard triple-beam interferometers have an angular measuring range of ± 1.5 angular minutes and a displacement measuring range of 2 meters. With length resolutions of 20 picometers, angles are resolved with < 0.002 angular seconds.

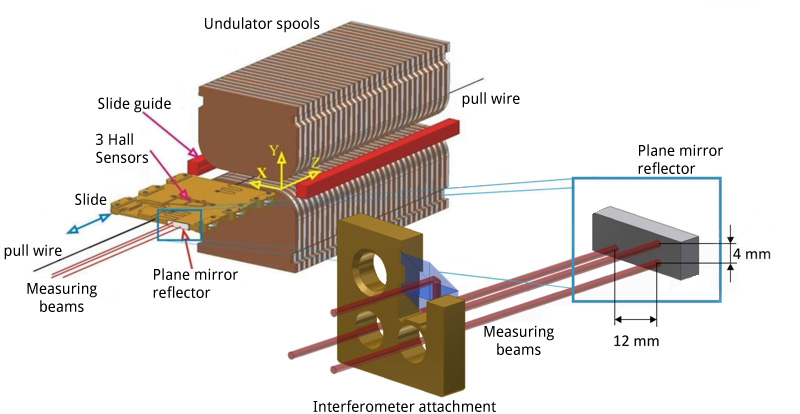

In a cooperative project with the Institute for Synchrotron Radiation at the Karlsruhe Institute of Technology, a special version of the Triple-Beam Laser Interferometer was used for high-precision alignment of the magnetic coils (undulators) in the electron storage ring. Undulators are periodic magnetic structures that are built into the straight sections of synchrotron radiation sources to generate highly brilliant synchrotron radiation. In the present case, they consist of two periodic arrays of superconducting undulator coils separated by the so-called undulator gap. The intensity and spectrum of the synchrotron radiation are determined by the period length and the strength of the undulator field, which in turn depends on the geometry and properties of the magnets.

For precise alignment of the undulator coils a measurement sled with three Hall sensors is pulled over a length of 2.5 m through a 4 mm tall slot between the coils. During the movement, the Hall sensors measure the local magnetic field along the beam axis as a function of the pitch and yaw angle of the measurement sled.

The pitch and yaw angle measurements are achieved with a modified triple-beam interferometer. In the standard triple-beam interferometer, the beam spacing between the three laser beams is 12 mm each. Using an optical attachment developed for this project, the vertical beam spacing of the interferometer was reduced to 4 mm in order to be able to measure in the gap between the coils. The angle determination is based on the high-precision and high-resolution laser interferometric length measurement by means of three partial beams over a length of 2.5 m.

The measurement takes place in a vacuum. The interferometer beams are guided through an optical window onto the mirror of the measuring slide. The following figure 2 shows the measurement task schematically.

The modular concept of the triple-beam laser interferometer allows complex customer-specific problems to be solved easily, as was demonstrated in the application case presented above.

Triple beam laser interferometer

simultaneous displacement and measurement of two angles