The Triple beam laser interferometer SP 5000 TR is a precision measuring device from SIOS for fast, highly accurate and simultaneous length and angle measurement. This results in a wide range of possible applications. While scientific laboratories and national measuring institutes expect the very highest accuracy, the numerous applications in the high-tech industry place great emphasis on the fact that the measuring systems can be used flexibly on the one hand and withstand industrial operating conditions on the other.

The interferometer is used, e.g.

as a laser interferometric precision length measuring system for installation in single and multi-axis measuring stages

in microscope stages, machine tools and positioning devices

as a measuring system for position control of single and multi-axis stages

for calibration of machine tools and coordinate measuring machines

Functionality of the Triple beam laser interferometer

The functional principle of the interference optical measuring system is based – like all SIOS laser interferometers – on the application of the Michelsons interferometer principle.

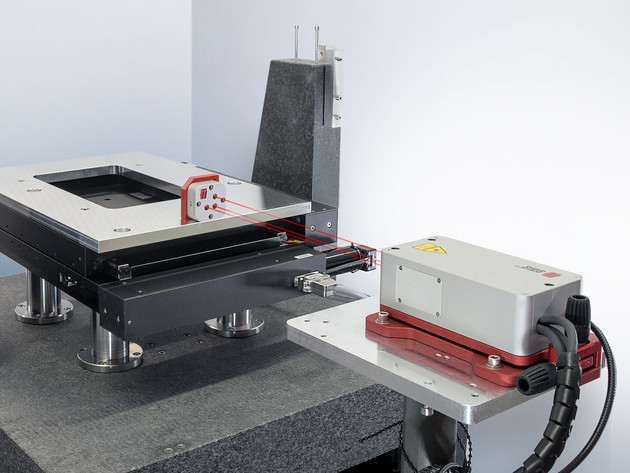

The Triple beam laser interferometer SP 5000 TR combines three interferometers in one device. The same highly stable long-term laser frequency stability of 2·10-8 of the HeNe laser is used in all three measuring channels. Thus, three length values can be measured simultaneously with nanometer accuracy. From the difference between two length values and the calibrated beam spacing, the corresponding angle can be determined with high precision, thus enabling the simultaneous measurement of position, pitch and yaw. In this way, high-precision simultaneous displacement and angle measurements are possible.

The laser interferometer has a displacement measurement range of 5 meters and an angular measurement range of ± 12.5° with a reflector. Thereby, the angular resolution is up to 0.002 angular seconds under stable environmental conditions. In the standard Triple beam interferometer, the beam spacing between the three laser beams is 12 mm each. Due to the simultaneous and highly synchronous acquisition of measured values, there is no falsification of the results even at a high object velocity of up to 3 m/s.

An adjustment joint is used as standard for adjusting the direction of the measuring beams. It enables the parallel alignment of the measuring beams with respect to the guide or measuring direction in a simple manner.

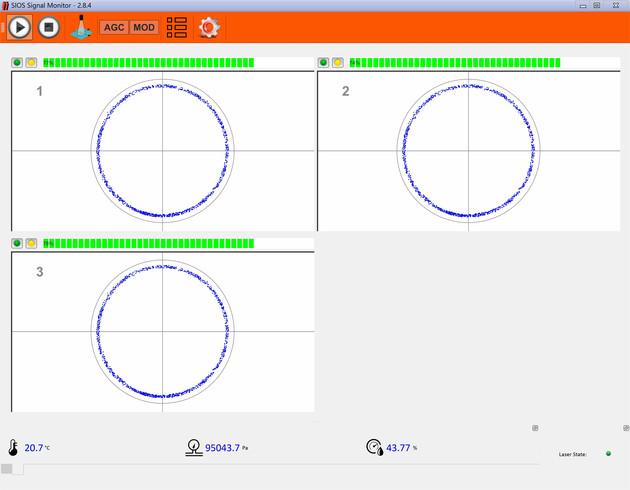

Thanks to the optical alignment aids integrated in the interferometer sensor, the correct alignment of the measuring arrangement can be performed quickly and easily using the graphical software interface of the SIOS Signal Monitor (see screenshot).

In this way, alignment-related measurement errors can be minimized.

Compensation of environmental factors

To ensure that the high-precision length and angle measurements are not adversely affected by heat input, the stabilized HeNe laser used as the light source is placed outside the sensor at an uncritical distance. Since the laser beam reaches the sensor head through a fiber-optic optical waveguide, there are only optical components in the sensor head that determine its functionality but do not cause any heat.

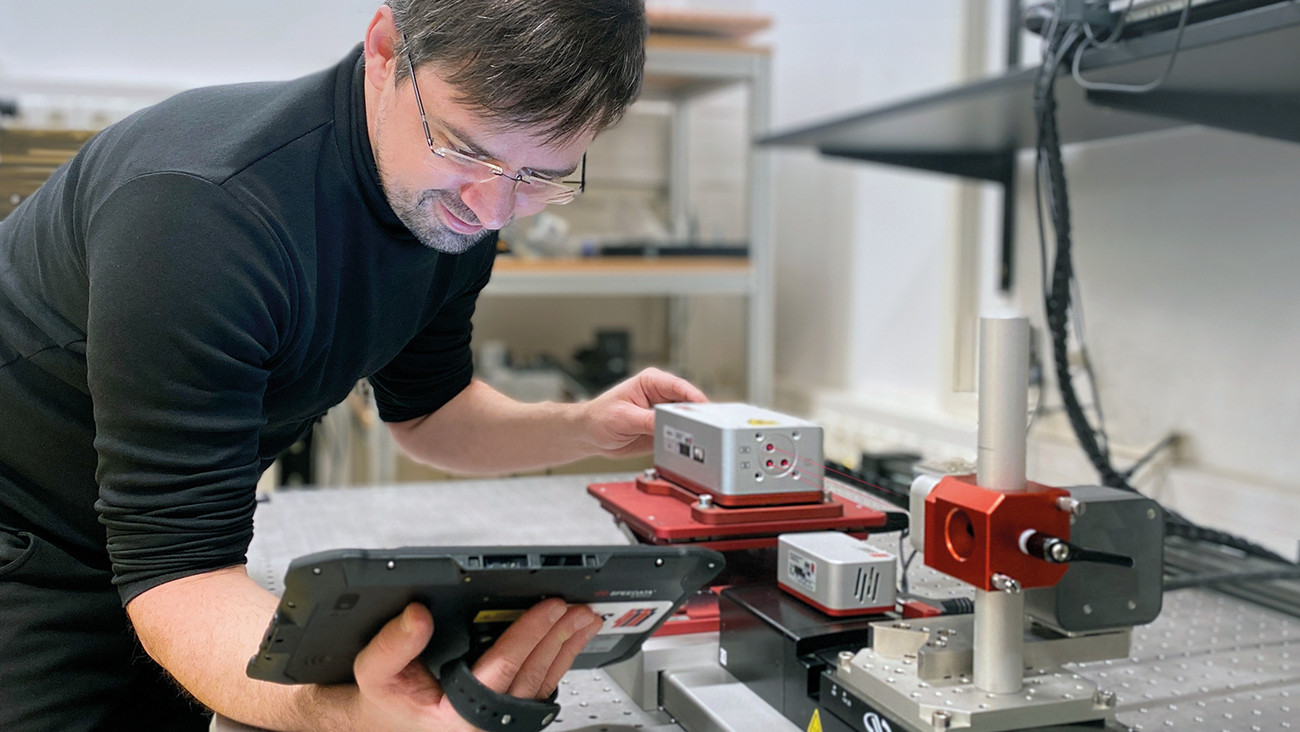

Especially with regard to the application in industrial environments, the interferometer sensor and the cables are furthermore completely protected. This means that the robust Triple beam interferometers can withstand even potentially dirtier environments.

The measurement result is strongly influenced by fluctuating environmental factors such as air temperature, air pressure or air humidity. With the help of wired or wireless measurement sensors and probes, the environmental variables are recorded and the measurement result is corrected accordingly. This achieves a very high measurement accuracy.

Measurement Software

The Triple beam interferometer is controlled via the InfasNTC, InfasMTCAL or InfasAXIS software, which is installed on an external PC. The metrology software allows the components of the laser interferometer to be controlled via a user interface. Alternatively, the laser interferometer system can also be controlled by customer-specific software.

Due to the modular design of the evaluation electronics, different interfaces can be used and a wide variety of device configurations can be realized.

Conclusion

Due to its compact design, the interferometer can be easily adapted to a wide variety of length and angle measurement tasks and integrated into existing arrangements. Several – identical or different – single and multi-beam interferometers can be combined if required. With a combined measurement setup, all six translational and rotational degrees of freedom can be measured simultaneously and used for precise position control. Only one supply and evaluation unit is required to operate several interferometers.

In order to meet the requirements of the various industrial applications, the interferometer is available not only as a standard version but also as a vacuum version and a special version as an OEM solution.

More information about the Interferometer System

For detailed information about the Triple beam laser interferometer SP 5000 TR, such as general product information, technical data sheet, technical article or dimension sketch, please refer to the product detail page.

Our webinar tip:

High-precision simultaneous displacement and angle measurement

SIOS experts provide insights into the theory and practice of length and angle metrology. You will learn, among other things, which factors have an influence on measurement uncertainties, how to realize an Abbe error-free measurement setup or how to compensate Abbe errors.

If you are not sure whether the laser interferometric measuring system fits your requirements for high-precision length and angle measurement, let us advise you.

We would be happy to provide you with a loaner device for initial trial measurements. Finally, we will help you with the installation of your device on site and are always available for advice and support.

You are interested in the SP 5000 TR?

We will be happy to make you a suitable offer.

Fields marked with * are required for processing.